1) Introduction:

Industries across Australia—from petrochemical plants in Western Australia to aerospace engineering hubs in Victoria—often face one common issue: material degradation under high temperatures and corrosive environments. Traditional stainless steels, while widely used, frequently fall short when exposed to prolonged thermal cycling or intergranular corrosion, leading to frequent maintenance, operational downtime, and costly replacements.

This is where Stainless Steel 321 Sheets come into play.

2) Product Introduction:

Stainless Steel 321 (SS 321) is a titanium-stabilized austenitic stainless steel developed to provide improved resistance to intergranular corrosion. It is essentially SS 304 with the addition of titanium, making it ideal for high-temperature applications.

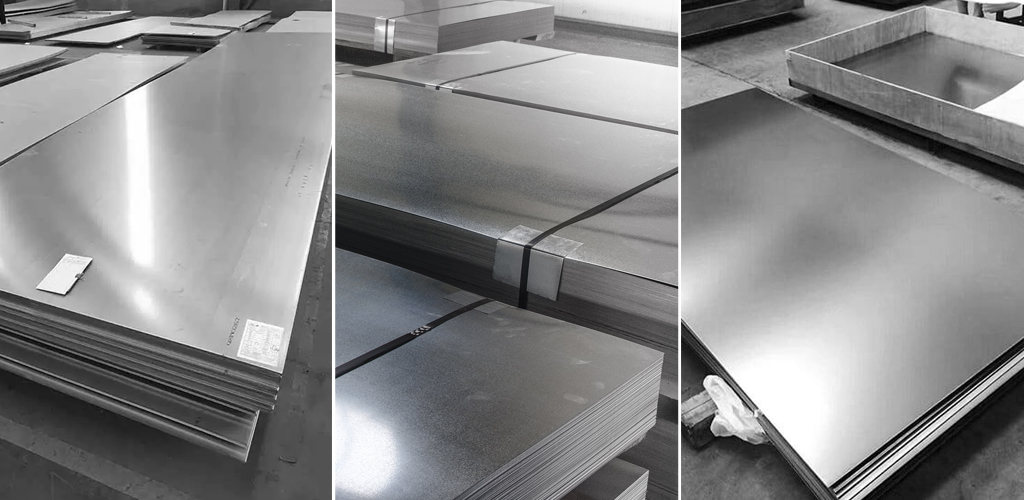

SS 321 Sheets are rolled, flat products known for their excellent strength and resistance to scaling at temperatures up to 900°C. These sheets are widely manufactured and exported by leading Stainless Steel 321 Sheets Manufacturers in India, supplying Australian industries with top-tier quality.

Technical Standards:

UNS S32100

ASTM A240 / ASME SA240

Equivalent to 1.4541 (EN/DIN)

Thickness range: 0.3mm to 100mm

3) Key Advantages of Stainless Steel 321 Sheets

???? Superior High-Temperature Strength: Performs exceptionally well in environments exceeding 500°C.

⚙️ Excellent Oxidation Resistance: Resists scaling and oxidation even in continuous service up to 900°C.

???? Improved Intergranular Corrosion Resistance: Titanium content prevents chromium carbide precipitation.

????️ Good Formability & Weldability: Ideal for fabrication, bending, and welding.

???? Resistance to Marine and Chemical Environments: Performs well in mildly corrosive and marine atmospheres.

4) Real-Life Applications in Australia

????️ Aerospace Industry: Used in exhaust manifolds and engine components.

⚗️ Petrochemical & Refineries: Suitable for heat exchangers, furnace components, and pressure vessels.

???? Marine Applications: Perfect for coastal infrastructure and shipbuilding.

???? Power Generation: Applied in boilers, superheaters, and flue gas scrubbers.

???? Automotive: Employed in turbocharger casings and exhaust systems.

5) How Stainless Steel 321 Sheets Solve the Problem

Australian industries often deal with extreme temperatures, corrosion from salt-laden air, and high mechanical stress. Traditional stainless steels like 304 or 316 may degrade over time, but SS 321 Sheets stand out due to their stabilized structure.

✅ Solution: The titanium in SS 321 binds carbon, preventing the formation of chromium carbides—thereby maintaining corrosion resistance at elevated temperatures.

✅ Outcome: Reduced maintenance costs, extended service life, higher safety margins, and improved operational efficiency. For instance, power plants using SS 321 in high-heat environments reported a 30–40% increase in component life span compared to conventional materials.

6) Conclusion: The Future of High-Performance Steel in Australia

Stainless Steel 321 Sheets are no longer just an alternative—they are the standard for high-temperature and corrosion-resistant applications. As industries across Australia aim for longevity, sustainability, and performance, SS 321 Sheets offer a future-proof solution backed by the reliability of trusted Stainless Steel 321 Sheets Exporters and Manufacturers in India.